High Quality Rotary Table China Manufacturer & Supplier

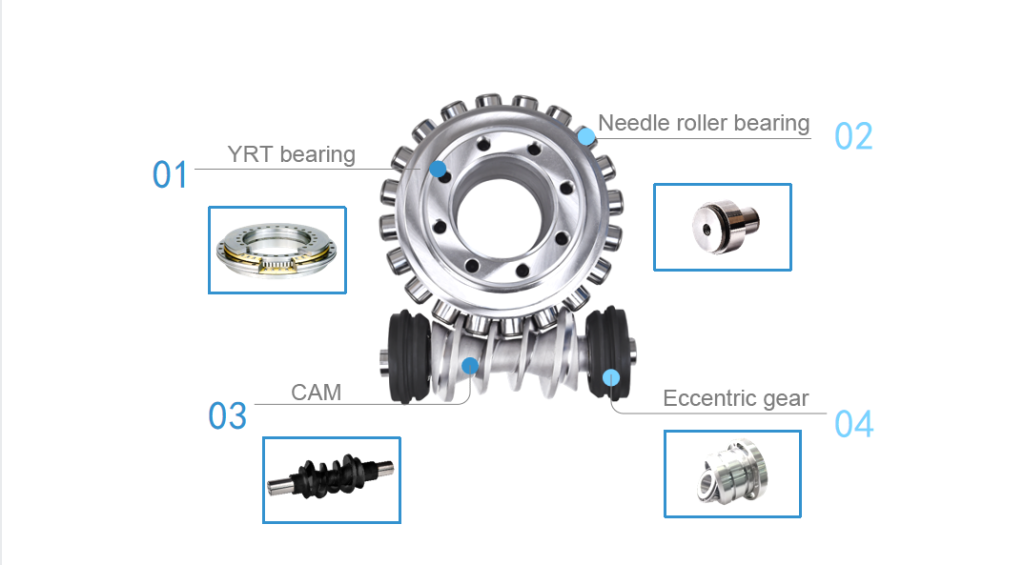

- Roller cam ensures stable accuracy, long service life and easy maintenance

- Both 4th axis and 5th axis rotary table are available

- Selecting simultaneous or single axis control according to your machine tool situation

- You can only choose the rotary table body, or our complete rotary table solution, including tailstock, manual chuck, motor, brake device, single axis controller, trunnion table.

- Absolute price advantage because of China has low manufacturing costs

- Customizable logo are always meet for agent worldwide

- MOQ is 1 set

SilverCNC offer large rang of rotary tables and accessories, multi axis machining by one-time clamping, which can improve efficiency and the accuracy of parts, it widely used in VMC, HMC, also can interact with various CNC controller systems , the Rotary Table is roller cam structure which is good wear resistance and long-lasting accuracy, We promise good quality, competitive price and fast delivery. Also OEM can be accpeted.

Leading roller CAM rotary table manufacturer, high precision and good stability, high rigidity and durability , One of the best-selling brands in China.

Rotary table is one of the most important components of CNC. Multi axis machining can be realized by one-time clamping, which can improve the production efficiency and the accuracy of parts, as well as shorten the cycle times. silver CNC rotary table can match with different brands of control systems, such as Fanuc, Mitsubishi, Siemens . widely used in automotive, aerospace, mold, parts machining and other industries. The rotary table almost the same quality but half price than some Japanese brands. We confirm that you will benefit if you use our rotary table. welcome to inquire and quote.

CNC Rotary Table For CNC Machining Centers

Our CNC rotary table including 4 axis , 5 axis tilting , cnc with rotary axis horizontal table for differents spec of machine tools, such as high speed vertical machining centers , drilling and tapping machines, HMC and so on .

-

Chambray Fringe Quilt Cove

Our denim quilt cover is the real deal. The genuine article. Enzyme washed, double stitched, complete with brass zippers on the euros, we just know youll end up loving this bedlinen even more than your favourite pair of jeans.Read More » -

Sunset Quilt Cover Set

Our denim quilt cover is the real deal. The genuine article. Enzyme washed, double stitched, complete with brass zippers on the euros, we just know youll end up loving this bedlinen even more than your favourite pair of jeans.Read More » -

Finca Quilt Cover Set – Dove

Our denim quilt cover is the real deal. The genuine article. Enzyme washed, double stitched, complete with brass zippers on the euros, we just know youll end up loving this bedlinen even more than your favourite pair of jeans.Read More » -

Finca Quilt Cover Set – Greystone

Our denim quilt cover is the real deal. The genuine article. Enzyme washed, double stitched, complete with brass zippers on the euros, we just know youll end up loving this bedlinen even more than your favourite pair of jeans.Read More » -

Chambray Fringe Quilt Cover – Dove

Our denim quilt cover is the real deal. The genuine article. Enzyme washed, double stitched, complete with brass zippers on the euros, we just know youll end up loving this bedlinen even more than your favourite pair of jeans.Read More » -

Denim Quilt Cover Set

Our denim quilt cover is the real deal. The genuine article. Enzyme washed, double stitched, complete with brass zippers on the euros, we just know youll end up loving this bedlinen even more than your favourite pair of jeans.Read More »

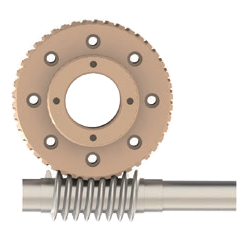

Roller Driver Zero Backlash Technology

Roller CAM Driver which uses the roller gear mechanism,The unit is constructed from an input shaft(the roller gearcam) and a turret(output shaft)fited with roller folowers. The roller followers are preloaded against a screw-like input shaft to completely eliminate backlash. Our proprietary adjustment mechanism provides optimum preload. The roller folowers planted in the turrt which use internal roler bearings to transfer torque while rotating.

Video About The Roller Cam Indexing Table Basic

Why Choose Silvercnc, What's Your Benefit

■ Firstly, we adapt roller CAM driver structure, it always no backlash, high efficiency conduction, no thermal displacement, long working life, which has good brake performance compared with worm gear and DD motor rotary table

■ Secondly , its quality is stability, almost no need maintenance

■ Thirdly, Price is reasonable, almost half of the price of American Haas for the same specification

■ And then, the rotary table use YRT bearing to ensure rigidity, and innovative structural design, material, machining process to ensure long working life

■ At last, with one year warranty, regular spare parts, customers no after-sales trouble

What mechanism is used in rotary table

Rotary table or cnc with rotary axisin market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Worm Gear

Rolleer Cam

DD Motor

Harmonic Driver

Roller CAM driver VS worm gear

Item | Roller CAM Driver | Worm Gear Type |

Appearance | ||

Contact | rolling contact | Slide contact |

Material | hardening steel ,HRC60 | Hardening steel ,HRC60 |

Hardness of the contact part | bearing steel ,HRC60 | Phosphor broze,HB90 |

Preload | YES | NO |

Transmission efficiency | Good | Worse |

Backlash | Alway zero-backlash | Necessary for rub strock |

Indexing accuracy | Under 20 arc-sec | 12-20 arc-sec |

High speed possiblity | Fast | Slow |

Flipping time | 0.5sec | 1.5sec |

Heating possibility | Low | High |

Rigidity | High | Low |

Durability | Good | Worse |

Backlash adustment | Unnecessary | Necessary |

Expansion of 5th Axis | Yes | No |

Repair fees | Low(replace needle roller bearings) | High (Replace the worm gear |

Maintenance costs | Low(do not adust) | High(Adusted once a year) |

Rotary table application video

Rotary Table Download

- Silvercnc rotary table catalogue

- 2D.3D-4th axis rotary table

- 5axis rotary table 3D models

- 5axis rotary table 2D drawing

- 2D.3D-H rotary table series

- Rotary table user manual

- Rotary table specification confirmation form

- Rotary table Packlist-EN

- Rotary table servo motors detail

- Rotary table tailstock specs